Blog

Sterile Peptide Filtration That Holds Up

If you have ever watched a clear peptide solution turn questionable after a clean reconstitution, you already know the hard truth: most “contamination events” are process events. The compound gets blamed, but the root cause is usually a preventable break in aseptic handling, an incompatible filter, or a workflow that was not designed to stay sterile from start to finish.

This article lays out a sterile peptide filtration protocol that fits real research workflows. It is not a substitute for your lab’s SOPs or your institutional requirements. It is a standards-focused framework you can adapt, document, and repeat.

When sterile filtration is appropriate (and when it is not)

Sterile filtration is a control step for solutions, not powders. You can only filter what is already dissolved, and filtration does not “fix” every problem.

It helps when you need to reduce microbial contamination risk in a peptide solution prior to aliquoting, short-term storage, or use in sterile downstream work. It is also useful when you want consistent handling across runs so that variability in technique is not the hidden variable.

It is not a remedy for endotoxin, and it is not a guarantee of sterility if your upstream handling is non-aseptic. A 0.22 micron filter is designed to retain bacteria. It will not reliably remove mycoplasma, viruses, or bacterial toxins. If endotoxin control matters for your application, you need an endotoxin-controlled supply chain plus appropriate testing and acceptance criteria.

Start with the right question: “What is the sterility target?”

A practical protocol depends on your target. If your goal is “reduce bioburden before aliquoting,” filtration plus clean technique may be appropriate. If you require sterility assurance for regulated work, you will need validated sterilization, environmental controls, and documentation beyond a bench-level process.

Sterile peptide filtration protocol: setup and materials

A clean protocol starts with controlling contact surfaces, airflow, and time exposed. Most failures happen in the setup stage.

Use a certified clean workspace appropriate for aseptic manipulation, typically a laminar flow hood or biosafety cabinet that is maintained and used correctly. Wipe down interior surfaces with an appropriate disinfectant for your facility, then allow the required contact time. If you do not respect contact time, you are just moving residue around.

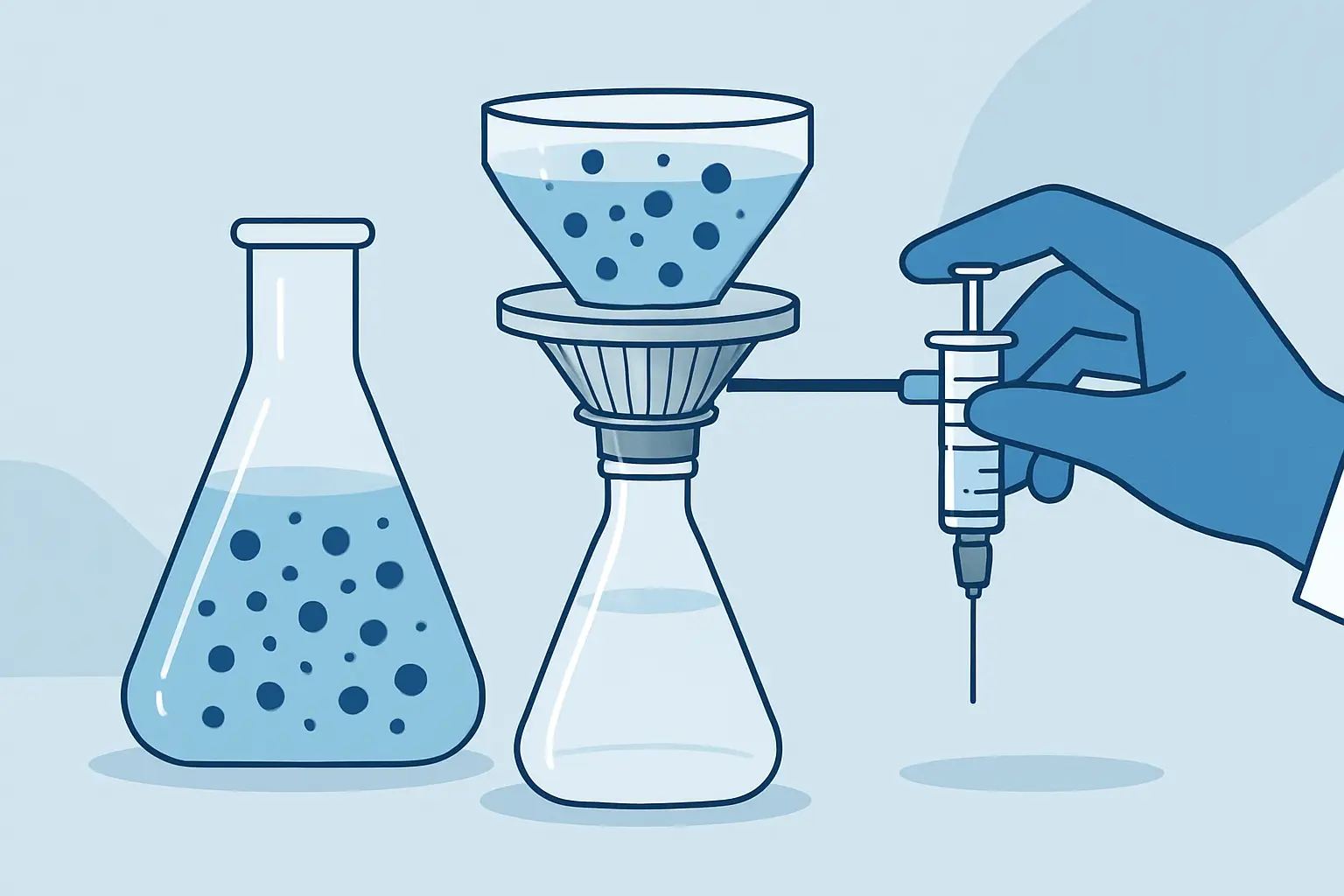

You also want to minimize “hand travel” over open sterile items. Arrange materials so the sterile pathway is short: reconstitution vessel, sterile syringe, sterile filter, and sterile receiving vial(s).

Filter selection: what matters in practice

Peptides are not all the same. Solvent choice and peptide properties drive filter choice.

A 0.22 micron sterile syringe filter is the common standard for bacterial retention. For membrane chemistry, PVDF is widely used for aqueous solutions with low protein binding, while PES is also common for aqueous filtration with good flow. Nylon can work for certain applications but can bind some analytes depending on conditions. If you are filtering solutions with organic modifiers, you must confirm chemical compatibility.

Do not treat “low binding” as marketing copy. Binding shows up as lost mass and inconsistent concentration, which can look like potency variability later. If concentration accuracy matters, document the membrane type and keep it consistent across projects.

Syringes, needles, and vials: keep the pathway sterile

Use sterile, individually wrapped syringes and filters. Use sterile receiving vials with intact closures. If you are piercing stoppers, use sterile needles and do not reuse them across vials.

If you are working with bacteriostatic water or other diluents, verify the container integrity, lot, and expiration. If you are using single-use sterile water for injection for research handling, the same applies. The point is not the label name. The point is controlled inputs and traceability.

Step-by-step sterile peptide filtration protocol

This workflow assumes you have a peptide in powder form that you reconstitute into a solution, then sterile-filter into a sterile vial for aliquoting or controlled use.

1) Prep the hood and reduce preventable exposure

Run the cabinet per your facility practice before beginning. Bring only what you need into the work area. Wipe down outer packaging, then open sterile items inside the hood without dragging wrappers across critical surfaces.

Wear appropriate PPE for your environment. Gloves should be clean and, if required by your SOPs, disinfected periodically during work. The goal is not perfection. The goal is consistency that you can repeat.

2) Reconstitute with controlled technique

Reconstitute using a sterile diluent and a sterile syringe. Add diluent slowly down the side of the vial when possible, rather than blasting directly onto the powder. Excess agitation can promote foaming or adsorption to surfaces for some peptides.

Let the solution fully dissolve. “Looks dissolved” is not always dissolved, especially at higher concentrations or with peptides that dissolve slowly. Undissolved material can clog filters and create unpredictable losses.

3) Choose whether to pre-wet the membrane

Some filters benefit from pre-wetting to reduce binding and improve flow, but it depends on membrane and solvent. If you pre-wet, do it with the same diluent you used for reconstitution and account for dead volume so you do not unintentionally dilute your final concentration.

If concentration is critical, dead volume is not a minor detail. Document it once, then use the same consumables so your correction factor stays valid.

4) Draw solution into the syringe with minimal bubbles

Attach a sterile needle or use the syringe directly depending on your container. Draw slowly to reduce air entrainment. Bubbles increase oxidation exposure and can complicate accurate volume transfer.

If you must remove bubbles, do it with the needle pointed away from sterile receiving containers and without sweeping your hands over open sterile surfaces.

5) Attach the sterile filter correctly

Maintain sterility at connection points. Do not touch the luer end that interfaces with the sterile filter. Once the filter is attached, keep the outlet protected until it is positioned over the receiving vial.

If you are filtering into multiple vials, understand that each additional manipulation increases risk. In many settings, it is cleaner to filter into one sterile intermediate vial, then aliquot using sterile technique, rather than repeatedly moving the filter outlet across multiple open targets.

6) Filter with steady, low pressure

Push the solution through the filter slowly and steadily. High pressure can cause foaming, can increase binding losses for some analytes, and can stress certain filter assemblies. If you feel strong resistance, stop and reassess. Resistance can mean undissolved particulates, precipitation due to solvent conditions, or simply a membrane that is not appropriate for the viscosity or volume.

If a peptide precipitates during filtration, you do not have a filtration problem. You have a formulation problem. Adjust concentration, diluent composition, or temperature within your research constraints, then reattempt with a documented change.

7) Cap, label, and control time-to-cold

Once filtered, cap immediately. Label with compound ID, concentration, solvent, date, and operator or batch reference. If you are maintaining repeatability, labeling is not administrative overhead. It is part of your control system.

Move the vial to the specified storage condition promptly. Time at room temperature can matter for certain peptides, especially if they are sensitive to hydrolysis or oxidation depending on formulation.

Common failure modes and how to prevent them

The same few issues show up repeatedly across labs.

Filter clogging is usually caused by incomplete dissolution, precipitation, or particulates introduced during handling. The fix is often slower dissolution, gentle mixing, and using a compatible solvent system, not forcing the plunger harder.

Unexpected loss of concentration is often binding to surfaces, especially with certain membrane chemistries or at very low working concentrations. If you are working near an assay’s limit of detection, even small losses can shift results. Using consistent membrane type and minimizing contact time with plastics can improve repeatability.

False confidence is the most damaging failure mode. A sterile filter does not compensate for a non-sterile receiving vial, poor hood discipline, or repeated stopper punctures with the same needle.

Documentation: what to record for repeatability

If you want outcomes you can defend, record the variables that change results.

At minimum, capture peptide identifier and lot, diluent type and lot, final target concentration and volume, filter pore size and membrane type, and the date and operator. If you are troubleshooting, also note whether you observed particulates, how long dissolution took, and whether you used pre-wetting.

This level of documentation also aligns with the way quality-first suppliers operate – consistent inputs, controlled handling, and traceable lots.

Sourcing and sterility: process still matters

Even with high-purity peptides, sterility is not automatic once you open a vial. Your filtration protocol is only as disciplined as your consumables and your upstream handling.

If you buy peptides for research, prioritize suppliers that emphasize lot consistency, identity verification, and clear handling expectations. Evergreen Peptides references research-grade testing and batch consistency as core quality controls, which is the right starting point for researchers who want fewer unknowns upstream. If you need a catalog built around those controls, see https://Evergreen-Peptides.com.

Trade-offs to decide upfront

Aseptic filtration adds time, consumable cost, and potential adsorption loss. Skipping filtration saves time but increases risk if your downstream work assumes sterile inputs.

It depends on your use case. If you are preparing a solution for sterile downstream procedures, filtration is typically worth the friction. If you are doing non-sterile analytical work where microbial growth is not a meaningful risk in the timeframe of use, filtration may be unnecessary and could introduce avoidable variability through binding.

The most defensible approach is the one you can repeat: same materials, same steps, same documentation, and a clear rationale for when filtration is required.

A good protocol does not try to be heroic. It makes the sterile pathway short, the decisions explicit, and the outcome predictable – which is exactly what research needs when results have to hold up under scrutiny.